Reduced Costs

The capital and operating cost is substantially less than traditional pre-treatment and primary sedimentation. There are also substantial cost savings associated with a drastically reduced footprint.

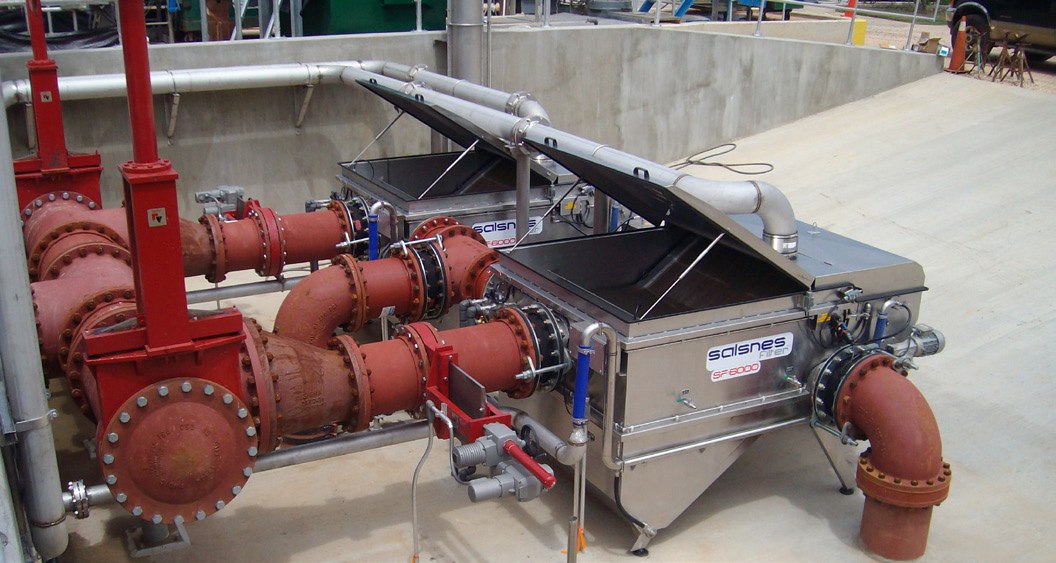

Small Footprint

A single compact Salsnes Filter can process up to 160 L/sec. This allows one to retrofit an existing facility & significantly improve performance without major changes to existing infrastructure.

Proven Engineering

All systems are pre-engineered & may be available in stock. Upon order of a new system it is possible to select the orientation of nozzles, etc to best fit into the facility.

Leading Performance

The filter is very effective at cleaning the wire cloth while maintaining a high capacity. The sludge produced is very dry and the compact unit provides a very high reduction in suspended solids.

In Norway fine mesh screens and sieves have been traditionally used for pre-treatment or even as the only treatment at smaller plants discharging into the ocean. Striving to achieve removal rates for primary treatment according to European Council Directive, (91/271/EEC) a fine mesh filter was designed that can remove as much as 50% suspended solids and 20% biodegradable organic carbon.

The Salsnes Filter is a low consistency (1% or less), high volume filter that has been designed specifically with Waste Water Treatment Plants in mind, and is most capable of replacing a Primary Settling Tank, or supplementing a Primary Settling tank to accommodate expansion and peak flow periods. All this at a fraction of the cost, and with a fraction of the required floor space, compared to conventional methods.

In addition to the removal of suspended solids from effluent (40-70%), the Salsnes Filter compacts and dewaters the removed solids to a dryness of 25 – 45%, providing incredible versatility to the industry.

Municipal Applications

For new wastewater plants, a Salsnes Filter system can completely replace conventional primary separation. For existing plants, primary solids separation can be augmented to improve plant performance and reduce overall costs.

Industrial Applications

To save costs, a Salsnes Filter system can recover both water and filtered material to be reused in the production process. Or, the system’s integrated thickening and dewatering can reduce sludge volume for disposal.

The system is completely automated, and a cost effective method compared to conventional waste water treatment methods, and is equally at home in industrial effluent handing situations, to reduce TSS, BOD and COD levels, and thus the effluent billing costs.

In South Africa where water is a scarce resource, and we are faced with the challenge of providing basic water and sewerage facilities to a vast population of underprivileged South Africans, mostly in outlying areas, the Salsnes Filter creates opportunities where no other method is viable, and will outperform conventional methods, providing a modular solution that can be adapted to suit specific applications.

Please take some time to review our website or feel free to contact us at any time should you require a PowerPoint Presentation to be sent to you via e-mail.