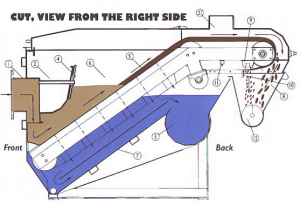

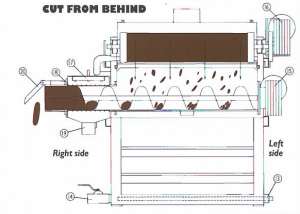

The wastewater flows through the inlet tube (1), filters through an endless wire cloth filter screen (2) where 40 to 80 % of the solids/sludge are removed. From the back of the wire cloth filtered water flows out through the outlet tube (3).

The wire cloth rotates and transports the separated solids/sludge to the air cleaning device (9) where compressed air blows the sludge down into the sludge compartment (8). First stage of dewatering is done by gravity during transport to the screw compartment. The screw presses the sludge forward to a press cylinder (18) where further dewatering is done. The dry solids concentration of the sludge can be regulated by adjusting the tension on the spring-loaded lid (20).

A pressure transmitter (4) measures the level of incoming water and this information is used to vary the speed of the wire mesh cloth to achieve optimum performance at variable flow rates and variable influent SS concentrations. As long as the water level in the inlet chamber of the sieve is low, the wire mesh cloth is immobile.

A pressure transmitter (4) measures the level of incoming water and this information is used to vary the speed of the wire mesh cloth to achieve optimum performance at variable flow rates and variable influent SS concentrations. As long as the water level in the inlet chamber of the sieve is low, the wire mesh cloth is immobile.

Eventually particles will accumulate on the cloth surface, the water level will increase and the pressure transmitter (4) will automatically start the motor (16) that moves the wire mesh cloth. If the water level keeps increasing while the cloth is moving, the speed will automatically increase. If the water level drops below a preset limit, the motor will stop until the level increases again.